Cryogenic particle detectors

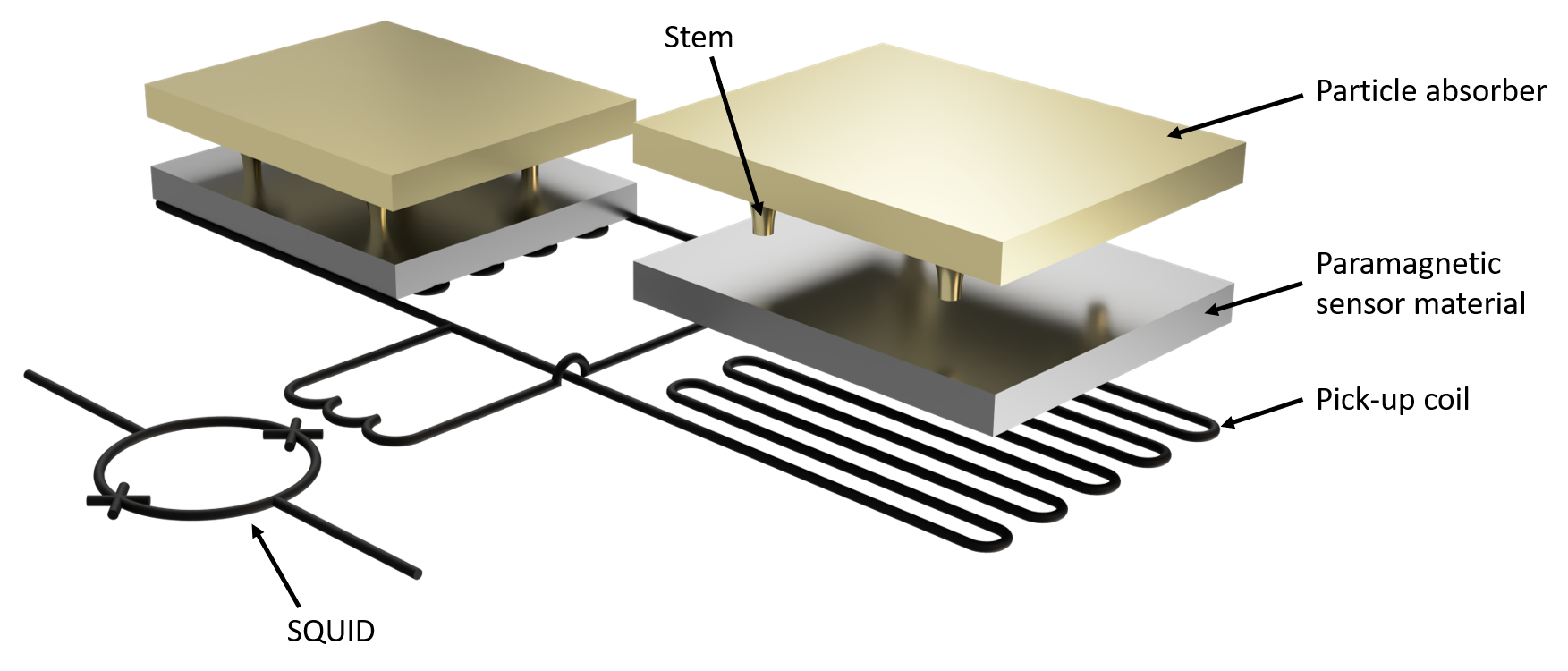

its most important components. The temperature sensor is read out via a

superconducting quantum interference device (SQUID).

The detection and energy dispersive measurement of single particles with high precision is a challenge facing many applications in research, society and industry today. The magnetic microcalorimeters (MMCs) developed and fabricated at the Institute of Micro- and Nanoelectronic Systems (IMS) are now an established tool in a wide range of applications, such as ultrahigh-resolution X-ray spectroscopy, determination of neutrino mass, radionuclide metrology or the search for dark matter.

The measuring principle of a magnetic microcalorimeter is based on the measurement of the heating of an absorber whose temperature changes due to the absorption of an incident particle. A paramagnetic sensor material is used as the thermometer, which is placed in a weak external magnetic field and therefore shows a temperature-dependent magnetization. Changes in this magnetization are measured using superconducting quantum interference devices (SQUIDs).

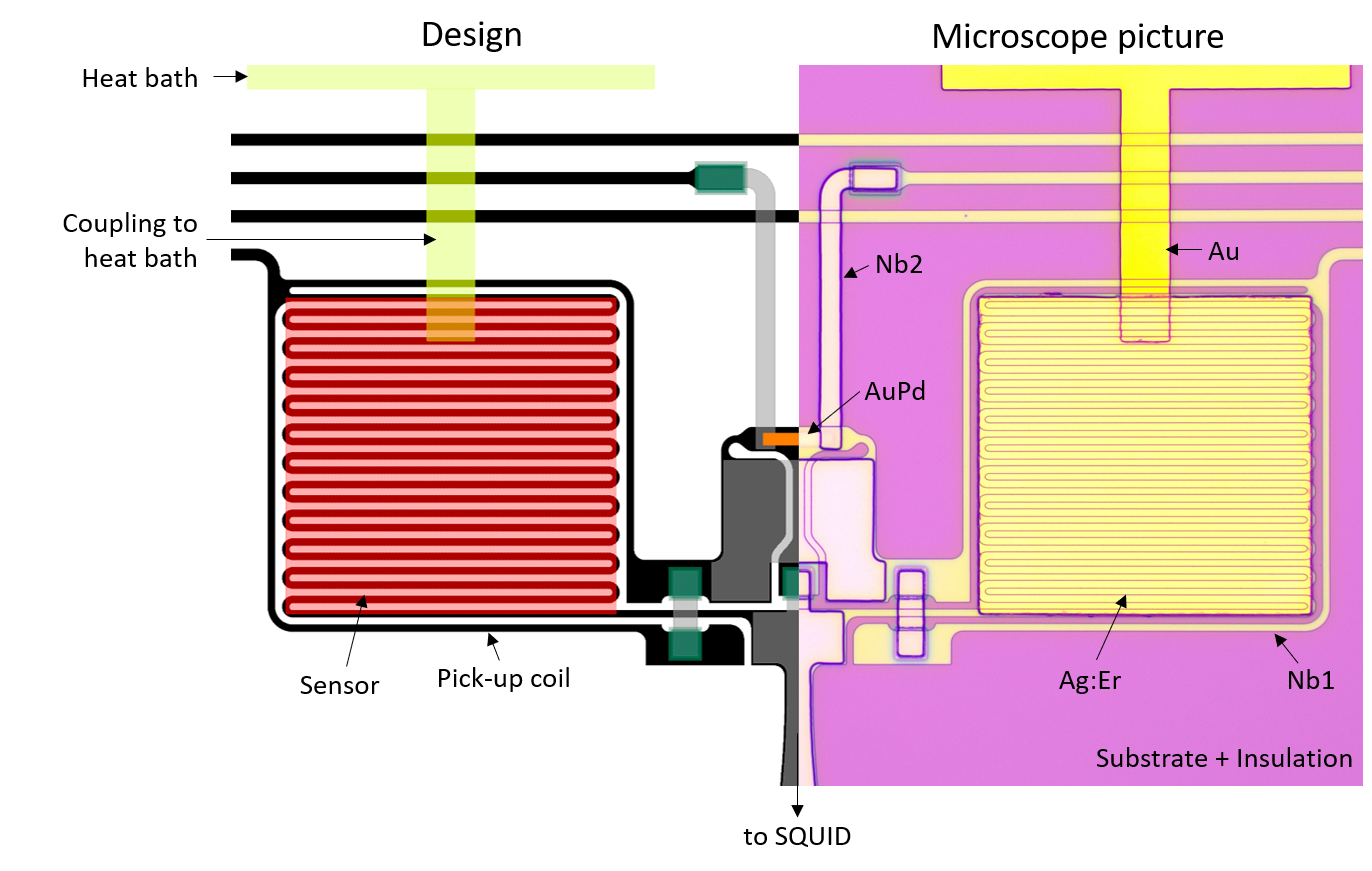

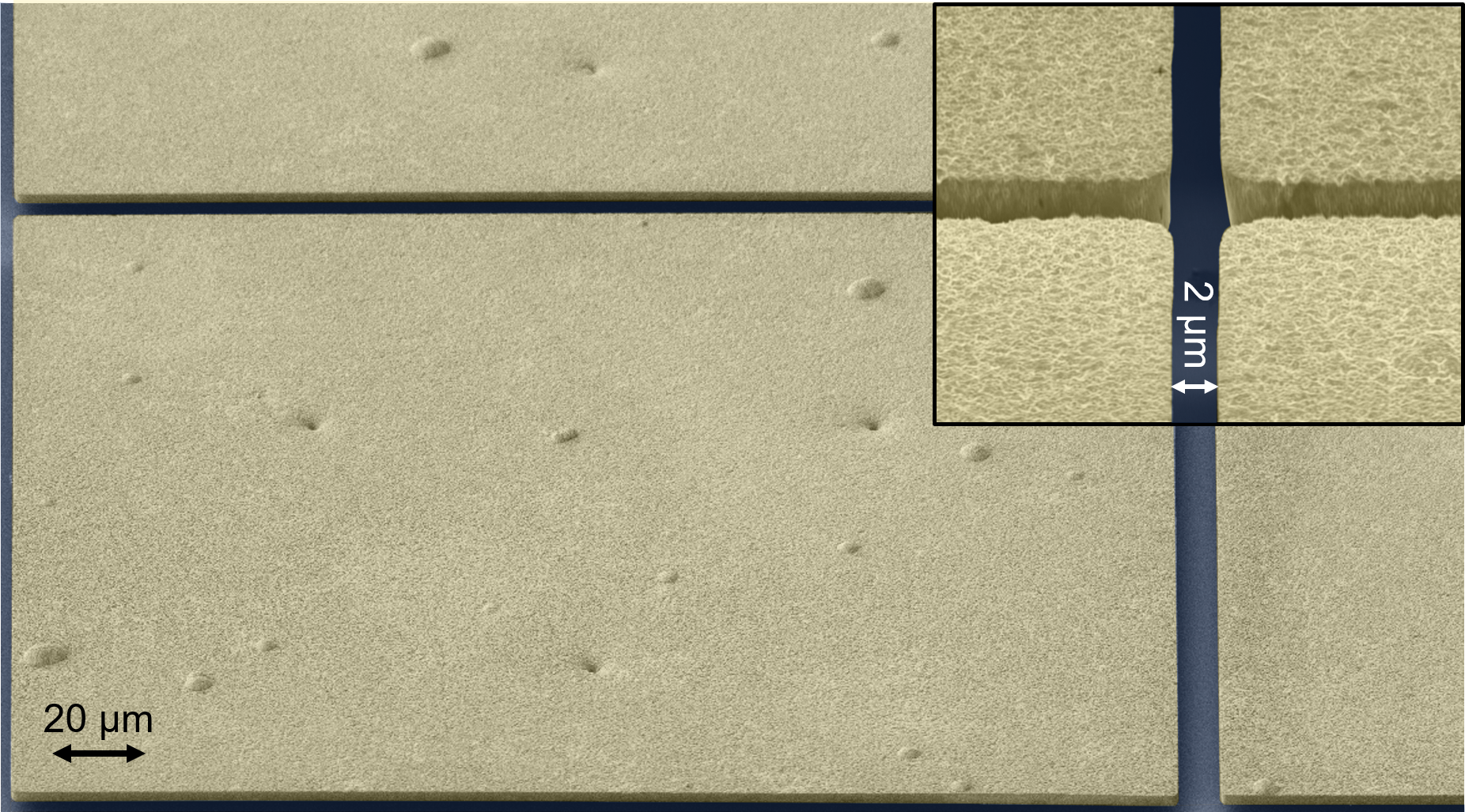

The optimal detector geometry of a magnetic microcalorimeter, which allows the best energy resolution, depends on the type of particles to be detected as well as their energy range. For this purpose, the detector geometry is optimized at the IMS for each application individually with the help of theoretical models. The result is translated into digital drawing afterwards. The detectors are then fabricated in the institute's own technology department on wafer scale using a variety of different materials in up to 30 successive process steps. The temperature sensor is applied to a substrate a few micrometers thick by sputter deposition and structured with the help of photolithographic processes. Superconducting coils made of niobium underneath the sensor are used to pick up the sensor signal and pass it on to the SQUID. On top of the sensor, the particle absorber made of high-purity gold is structured free-standing on stems, which enables a significant improvement in energy resolution. After microfabrication is completed, the detectors are usually characterized in a dilution cryostat, such as is also available at the IMS, and used for a wide variety of experiments. While single SQUIDs are used for the readout of a small number of detector pixels, the development of microwave SQUID multiplexers is being pursued at the IMS to enable the scalability of the already existing detector systems to imaging detector arrays with several thousand pixels.

of a detector pixel for high-resolution measurement of the decay

spectrum of 55Fe within the EMPIR project "PrimA-LTD" before

fabrication of the particle absorber.

free-standing on stems with a layer thickness of about 4 µm.